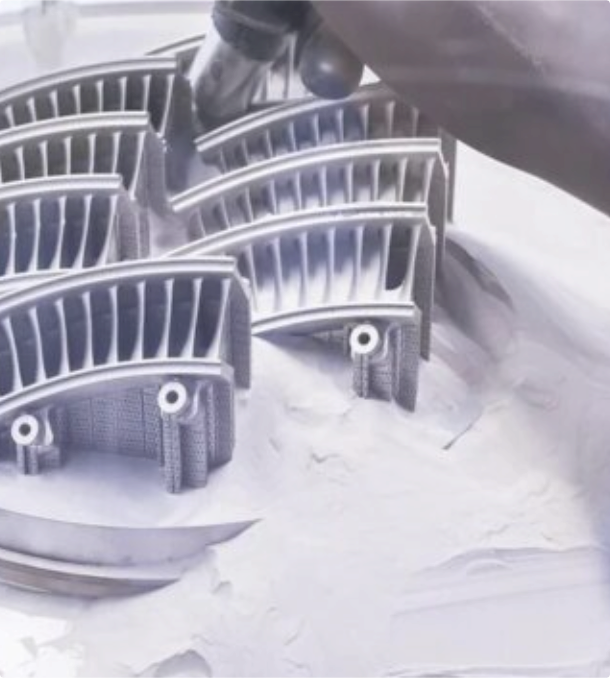

Metal 3D Printing Solutions for Energy

SLM 3D printers play a pivotal role in transforming the energy sector by enabling the production of complex and high-performance components. For example, SLM technology facilitates the creation of lightweight yet durable parts, optimizing energy efficiency and operational reliability. Components such as turbine blades, heat exchangers, and customized sensors can be precisely manufactured with SLM, enhancing equipment performance and longevity. Additionally, the design flexibility of SLM allows for rapid prototyping and customization, supporting innovation and accelerating the development of next-generation energy solutions.

SUCCESSFUL STORIES

Laseradd Material for Energy Applications

Laseradd offers a wide range of qualified metal powders compatible with our SLM systems. All materials provided by Laseradd are qualified for their chemistry, spherical structure, particle size distribution, dryness, and flowability.OUR MATERIAL PORTFOLIO COMPRISES

-

1

Ni-Based Alloys: IN625, HX, IN718, IN939

-

2

Fe-Based Alloys: 316L (1.4404)

-

3

Cu-Based Alloys: CuSn10

Devices that you may interested