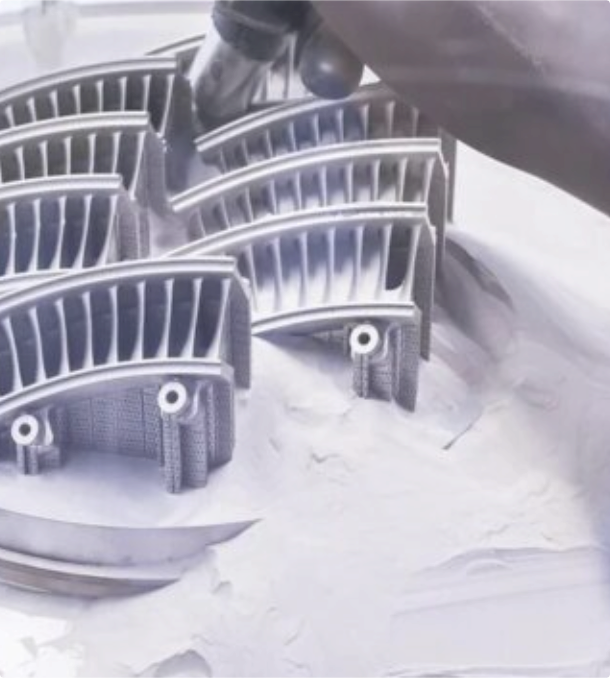

Metal 3D Printing for Healthcare

Medical device manufacturers are increasingly embracing SLM technology for a wide range of medical devices and dental prostheses. SLM serves as an ideal production method, seamlessly integrating functionality into components. For instance, lattice structures for surgical implants enhance osseointegration and minimize stress shielding. SLM efficiently produces complex bionic geometries tailored to customized patient anatomy. This innovative technology offers significant productivity and cost advantages over traditional processes such as casting and machining.

SUCCESSFUL STORIES

Laseradd Material for Healthcare Applications

Laseradd offers a wide range of qualified metal powders compatible with our SLM systems, commonly used in the healthcare industry. All materials provided by Laseradd are qualified for their chemistry, spherical structure, particle size distribution, dryness, and flowability. We provide validated process parameters for all biomaterials on all our machines.OUR MATERIAL PORTFOLIO COMPRISES

-

1

Ti-Based Alloys: Ti6Al4V Gd. 23, Ti (Grade 2),TC-4,T0

-

2

Co-Based Alloys: CoCr28Mo6, CoCrMo, CoCrMoW

-

3

Stainless Steel: 316L (1.4404), 17-4PH (1.4542)

Devices that you may interested