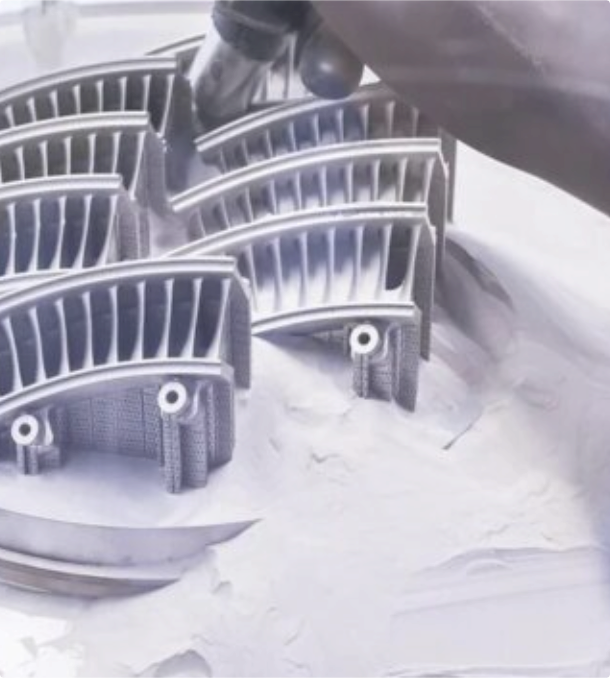

Metal 3D Printing Solutions for Tooling

Selective Laser Melting (SLM) is increasingly embraced within the mold and tool industry. The geometric freedom brought by additive manufacturing has been leveraged to create innovative designs, components, and products with unprecedented complexity and functionality. Besides, SLM offers rapid prototyping capabilities that allow manufacturers to quickly iterate designs and produce prototypes for testing and validation, significantly accelerating development cycle. Time savings and streamlined processes not only enhance efficiency but also lead to cost reductions in the production of small-volume products.

SUCCESSFUL STORIES

Laseradd Materials for Tooling Applications

Laseradd offers a wide range of qualified metal powders compatible with our SLM systems. All materials provided by Laseradd are qualified for their chemistry, spherical structure, particle size distribution, dryness, and flowability.OUR MATERIAL PORTFOLIO COMPRISES

-

1

Fe-Based Alloys: 316L (1.4404), 1.2709, H13 (1.2344)

-

2

Co-Based Alloys: CuNi2SiCr

Devices that you may interested