DATA SHEET

| Laseradd DiMetal-M150E SLM 3D Printer | |

| External Dimensions(L*W*H): | 1280×860×1780mm (50.4X33.9X70.1 in) |

| Build Cylinder Size(L*W*H): | 150×150×150mm(5.91X5.91X5.91 in) |

| Scanning Speed: | 7.8m/s |

| Laser Type: | Fiber Laser 200W(Other power lasers are optional) |

| Galvanometer: | High Precision Scanning System |

| Inert Gas Protection: | Argon/Nitrogen |

| Powder Delivery: | Double Cylinder One Way Powder Feeding |

Advantages

-

1

High precision and high quality printing

High-precision scanning galvanometer, high precision and strong stability

-

2

Fresh air protection system

The efficient operation of Laseradd fresh air system and the field lens air shower shielding protection ensure high quality and high precision in 3d molding.

-

3

Full pop-up position system

More convenient and quicker to replace metal powders, and 100% eliminates cross powder contamination when replacing powders

-

4

Fully sealed vacuum chamber

The manufacturing environment has low oxygen content, ensuring that the metal is not oxidized and is compatible with powders of different specifications.

Samples

-

Dental Crowns

Build Data

• Kings M150

• Cobalt-Chrome

• 30 µm layer thickness

• 220 crowns for around 4h -

Hip Joint Implant

Build Data

• Kings M150T

• TC-6

• 30 µm layer thickness -

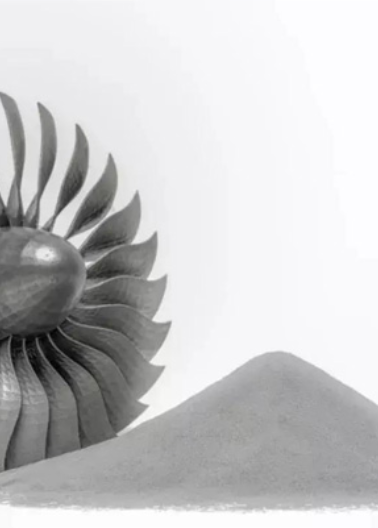

Jet Engine Bracket

Build data:

• Kings M150

• 316L stainless steel

• 50 µm layer thickness

ACCESSORIES

-

Air filteration system

The air filtration machine captures and filters out airborne particles and fumes generated during the metal 3D printing process. It also filters and supplies gas to the printing chamber, ensuring a stable gas environment, maintaining high printing quality, and protecting optical components.

-

Water cooler

A water chiller is used to regulate and maintain the temperature of the 3D printer and its components by circulating chilled water. This machine can prevents overheating of the printer and its laser systems, ensuring stable and efficient operation, and extending the lifespan of the equipment.

-

Explosion-proof wet vacuum cleaner

Designed to safely collect potentially explosive or flammable metal powders used in the 3D printing process, so to ensures a clean and safe working environment by preventing dust accumulation and potential ignition sources, reducing the risk of explosions.

-

Drying Oven

To remove moisture from the collected metal powders for future use.

-

Oscillating sieving machine

To sieve metal powders, ensuring that they are of uniform particle size before being used in the 3D printing process. This powder-treating process enhances print quality and consistency by removing oversized or undersized particles from the powder, ensuring smooth and even powder distribution during printing

Consumable

-

1

150*150mm 45# forming plate*4pcs

Aluminum alloy forming plate is optional

-

2

Filter Core

Filter element for air circulation device*4pcs, each one can be used 300 hours

-

3

Soft recoating blade

10 units, suggest to change each month

Material

-

1

316L,Ti6AI4V,AISi10Mg,In 718,CuSn10,CoCr,18Ni300 etc,

The normal particle size of powder is 15~53 microns, Other sizes can be customized